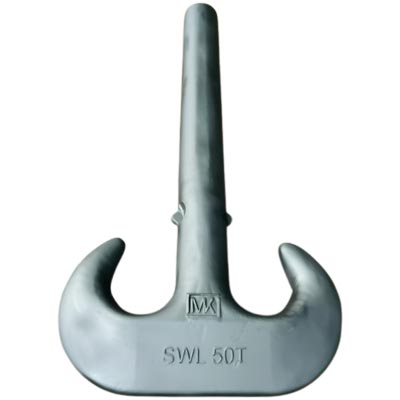

RAMSHORN HOOK

Ramshorn hooks are a type of double hook primarily used in heavy-duty lifting applications, such as shipyards, steel mills, offshore platforms, and large gantry or overhead cranes. Here's a detailed overview of the specifications and features of Ramshorn hooks:

Specifications

Material

Forged High-Tensile Alloy Steel, Heat-treated (quenched and tempered) for durability and strength.

Load Capacity

Typically ranges from 20 tons to 500+ tons. Designed to distribute load evenly across both horns, reducing stress concentration.

Standards & Compliance

DIN 15402 (Part 2 for double hooks), ISO 7597, ASME B30.10, or customized to customer specs, CE certification for European markets, where applicable.

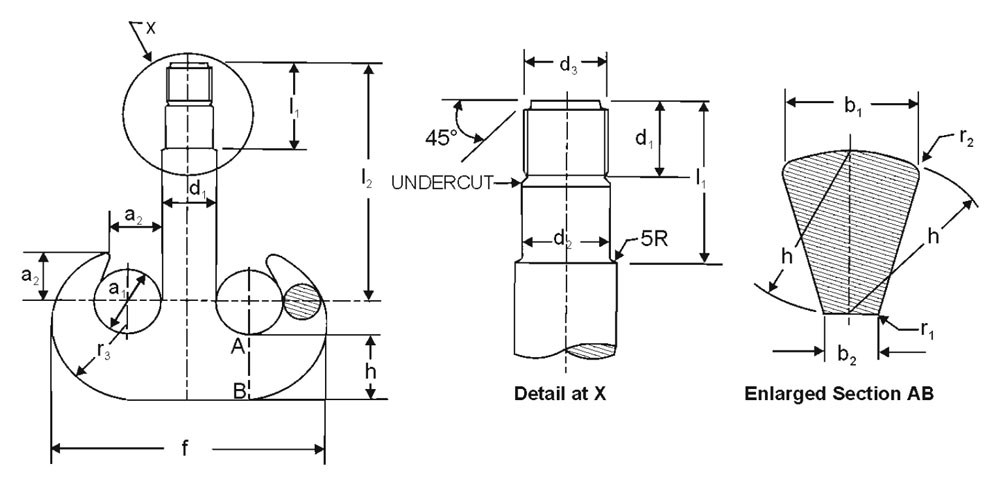

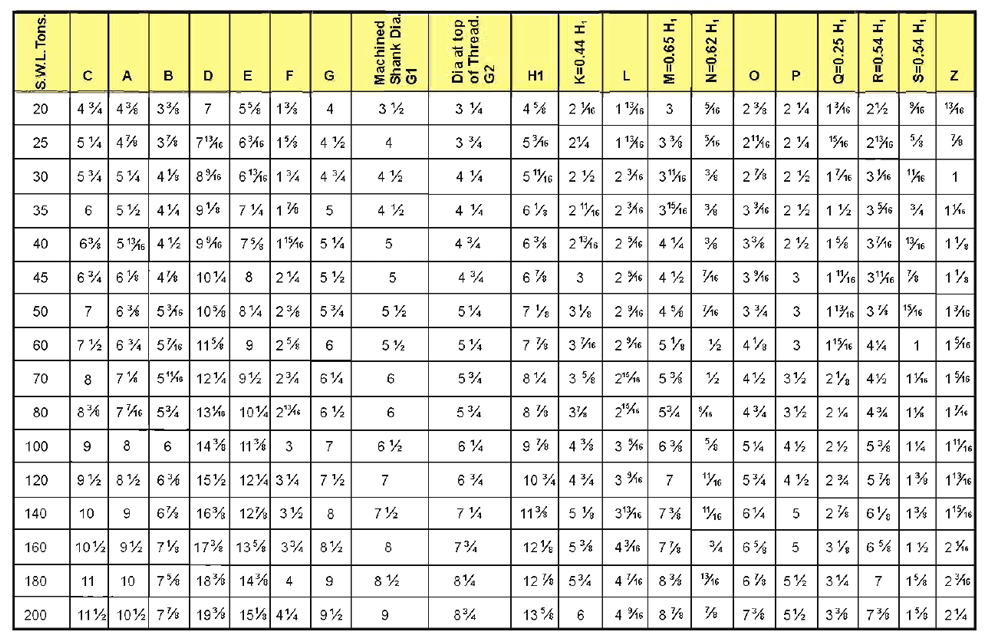

Dimensions

Typical dimensions include: Hook Opening (Throat Width), Center Distance Between Horns, Hook Height, Overall Length and Width, Shank or Eye Size (for mounting into the hook block). These dimensions vary depending on the lifting capacity and are defined in DIN 15402-2.

Key Features

Double Hook Design

Distributes the load between two horns. Reduces bending stress and provides higher stability during lifts. Ideal for lifting long, heavy, or unbalanced loads

Integrated Safety Latches

May include dual latches on each horn for securing slings or links. Spring-loaded or mechanical self-locking.

Swiveling Mechanism

Typically mounted on a hook block with a bearing or thrust mechanism. Allows 360° rotation under load for precise load positioning.

Identification Markings

Load rating (WLL), Manufacturer's logo or name, Serial number, Standard compliance mark.

Wear Indicators

Grooves or lines on the hook to visually indicate permissible wear. Designed to ensure safety and allow for early replacement.

Surface Finish

Anti-corrosive paint or galvanization, Available with marine coating for offshore applications.